The linear axis used for providing power, performing motion tasks, and positioning tasks should be effective and reliable, but at the same time, it should also be efficient - ideally, its efficiency can run through the entire product lifecycle: from the initial engineering design to the final maintenance and service. Bosch Rexroth's modular plug and play solution CytroForce proves that servo hydraulic shafts can also be easily configured and used with low maintenance costs, making them a ready to use product out of the box. What new fields has this product opened up, and in which potential areas has it helped achieve cost savings? Let's take a look together!

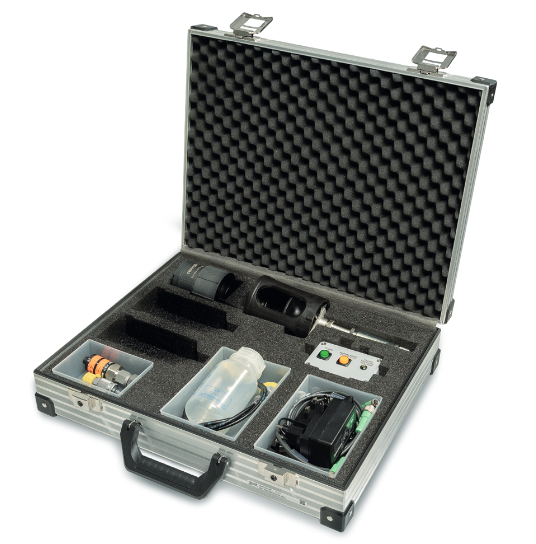

The CytroForce servo hydraulic actuator consists of a servo driver, pump, and integrated oil cylinder, which can achieve closed-loop control and plug and play.

CytroForce is a ready to use delivery solution composed of modules optimized for traffic, which has established new benchmarks in power density, energy efficiency, and operating noise. This solution is plug and play once delivered. Even equipment manufacturers with limited hydraulic experience can benefit from this unfamiliar application product and minimize the total cost from engineering to maintenance.

Feature

- Pre configured actuators based on reliable Rexroth components

- High power and performance: performance range from 40 to 1200 kN

- Maximum travel distance of 1.0 m

- The maximum speed can reach 0.8 m/s

- Extremely compact: a complete hydraulic system that is compact and does not require additional piping

- Efficient and energy-saving: driven by a variable speed pump

Four potential benefits points

1 .Simple Engineering Design

One of the main goals of CytroForce is to enable people to utilize the special advantages of servo hydraulic shafts even without any hydraulic expertise, and greatly reduce the engineering burden on equipment manufacturers. The process is simple: Bosch Rexroth salespeople can guide customers through configuration through face-to-face or virtual meetings - defining loops and checking installation space through specific product design tools, input forces, speeds, and paths. During the configuration process, the customized servo shaft is ready "at any time" for production, which means it can be shipped within 12 weeks after placing an order. The quotation and technical documents will be sent in PDF format no later than the next working day.

2. Reduce overall costs

Compared to traditional hydraulic solutions, CytroForce can reduce energy costs by 80% throughout its entire lifecycle depending on different application scenarios. Due to a 97% reduction in oil consumption, traditional hydraulic power units are no longer needed, and the required space is correspondingly reduced by 50%, further saving costs. The standardized plug and play interface helps simplify the debugging process, as the pre configured servo axis can be treated as an electric drive device at the control level, so only electrical and higher-level control systems need to be connected, which is also a positive cost factor. The entire system is closed and requires extremely low maintenance.

3 .Higher Productivity

Excellent performance data, shorter cycle times, and lower overall costs mean sustainable improvements in productivity. Only half of the installation space is required for non integrated linear shafts, and the energy consumption of variable speed drive is 80% lower than traditional hydraulic systems. Compared to open systems, the low fuel consumption required is also beneficial from an economic and ecological perspective. For example, a standard hydraulic shaft containing a fuel tank and power unit requires 100 to 250 liters of oil, while a CytroForce shaft only requires 3 to 15 liters of oil, which can reduce up to 97%.

4.Improved availability

Closed and low maintenance hydraulic systems have a positive impact on availability. Unlike traditional hydraulic shafts, it has no dust that can enter the system, which means there is no need to frequently replace filters. It can also reduce downtime through status monitoring. Through integrated sensors and open interfaces, authorized entities can read and analyze data critical to faults and failures, and even perform predictive analysis through ODiN. The operational status index of the entire hydraulic shaft and each individual component related to the fault can provide effective indicators for process improvement and predictive maintenance.